Client

Black Start Solutions for Reliable Power Restoration

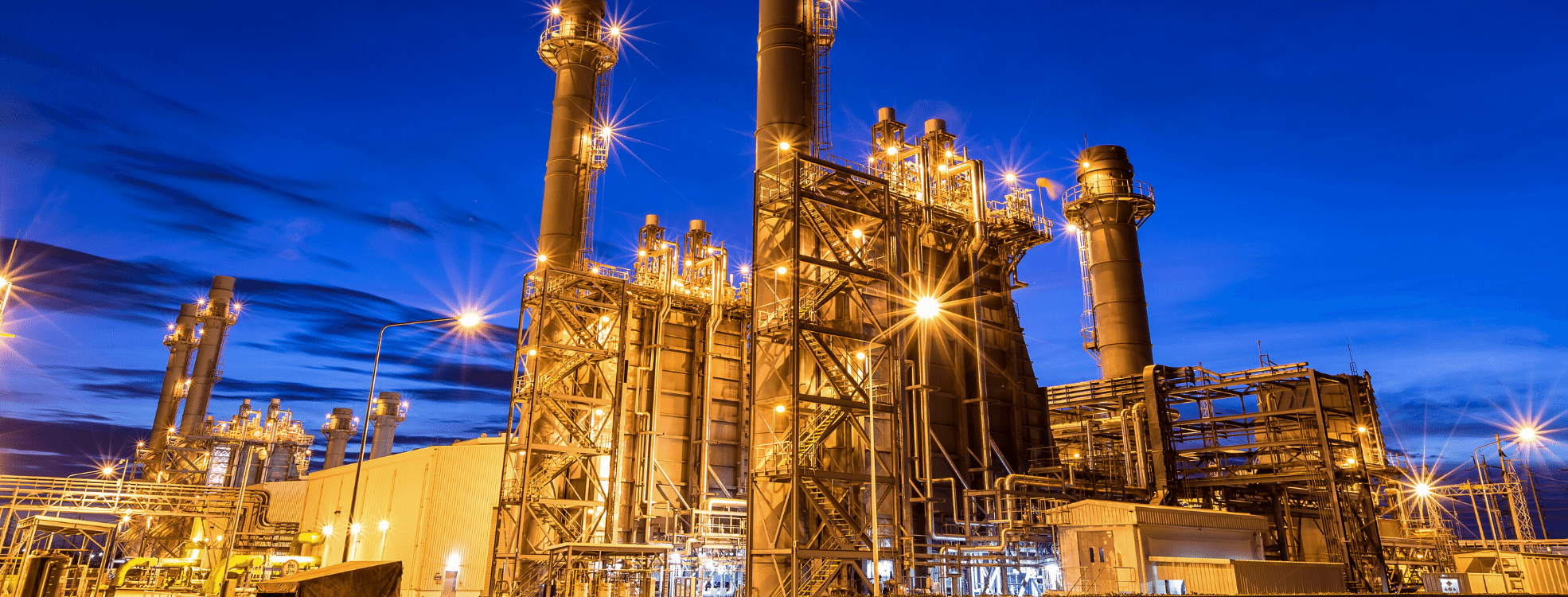

Ensuring Power Station Resilience with Black Start Solutions

What is a Black Start?

A black start is the process of restoring a power stations operations without relying on an external power transmission network. It allows the station to independently generate the power needed to restart its systems. While often associated with recovering from grid-wide outages, a black start also plays a crucial role during planned maintenance, such as annual service and repair works, to ensure seamless operations.

For power stations supplying the national high-voltage electricity network, black start solutions are essential to maintaining operational resilience. Temporary power solutions deployed during scheduled works enable power stations to continue their critical role in supporting the energy grid without interruption. These solutions also prepare stations to respond effectively to unforeseen disruptions, safeguarding the stability of the electricity network.

Power Resilience During Maintenance

The term “black start” was coined during the 2003 Manhattan blackout, which left 50 million people without power for over two days. Within just three minutes, 21 power plants failed, exposing vulnerabilities in backup power systems. Many mission-critical facilities discovered their standby generators were not as reliable as expected, and some had not been properly maintained or tested for years.

For the UK power station featured in this case study, implementing a black start restoration was a critical step during its annual service and repair works. This planned use of temporary power ensured the station’s systems could remain operational and ready for any potential disruptions. By employing black start during scheduled maintenance, the station safeguarded its ability to support the national power grid and reinforced its role as a vital part of the electricity supply infrastructure.

Project Summary

MEMS technical survey team attended the site to assess load requirements and engineer the most effective solution for the client. Following the assessment, MEMS provided a sustainable temporary power solution utilising three 800 kVA fully acoustic, containerised rental generators operating in a load on demand application. The load on demand application would provide the client with a reliable, efficient, yet scalable solution. Each generator was supported by an auxiliary fuel tank with MEMS Connect providing live monitoring of the equipment with data fed back to MEMS 24/7 control centre.

Each generator was connected to the temporary main distribution board via 25 metres of appropriately rated insulated cable with power lock connectors. From the main distribution board, six sub-boards were fed, each positioned 50 metres away housing 24x63A TPN C-Form outlets. Each outlet was protected by a type D breaker with adjustable RCD protection, allowing the client’s contractors to safely connect their equipment to the supplied outlets.

With built-in resilience, the system design enabled MEMS to perform planned preventative maintenance on the equipment without any power interruptions. Generators could be individually taken out of the load on demand grouping for servicing and seamlessly reintegrated without affecting the system’s performance.

The Results

The power station operated continuously, powered by a smart, sustainable MEMS solution, with no interruptions throughout the twelve-week hire period. MEMS managed the entire project, providing 24/7 services supported by a comprehensive solutions management team.